Barcode Types

Barcodes make warehouse transactions faster and more accurate by turning key inventory data into a reliable scan. In receiving and inventory handling, labels typically combine machine-readable barcodes and human-readable text so operators can scan quickly and still verify what they’re handling.

For warehouse receiving and inventory labels, these are the most common barcode formats:

- Code 39 (3 of 9)

- Code 128

- 2D barcodes (QR Code and DataMatrix)

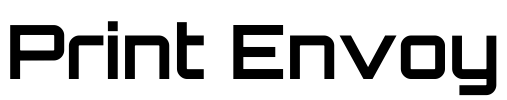

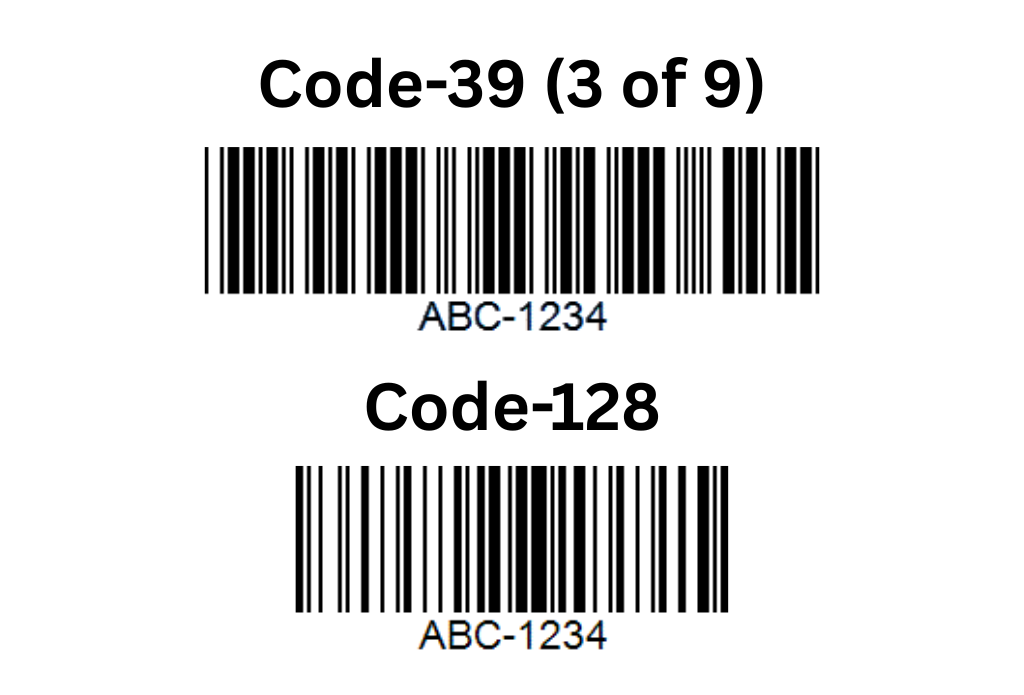

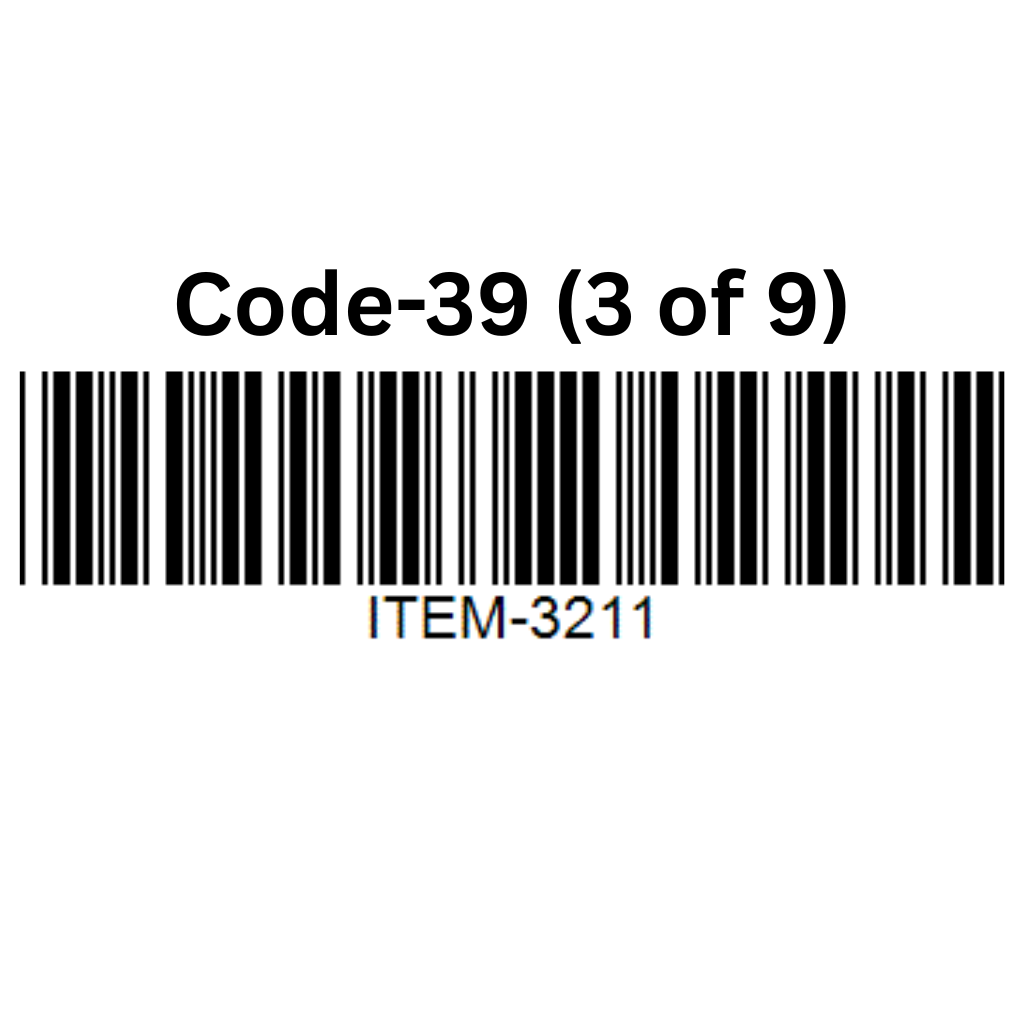

Code-39 (3 of 9)

Code 39 is a widely used 1D barcode for labeling goods across many industries. It’s popular for internal tracking because it’s simple, flexible, and works with almost any barcode scanner. It can encode both numbers and letters, but it’s not as compact as Code 128, so it requires more label space, especially when the value gets longer.

Why people use Code 39

- Works with most barcode scanners (great compatibility)

- Supports letters + numbers (good for internal IDs)

- Easy to generate and commonly used for asset, part, and location labels

Limitations

- Less compact than Code 128 (needs more horizontal space)

- Lower data density, so very long values can be harder to scan if print quality is poor

- Not ideal for very small labels/items

- If you want extra safety, use a checksum to help validate scan accuracy

Best suited for

- Internal item/part numbers

- Asset & equipment labels

- Warehouse location labels

- Environments where compatibility and simplicity matter most

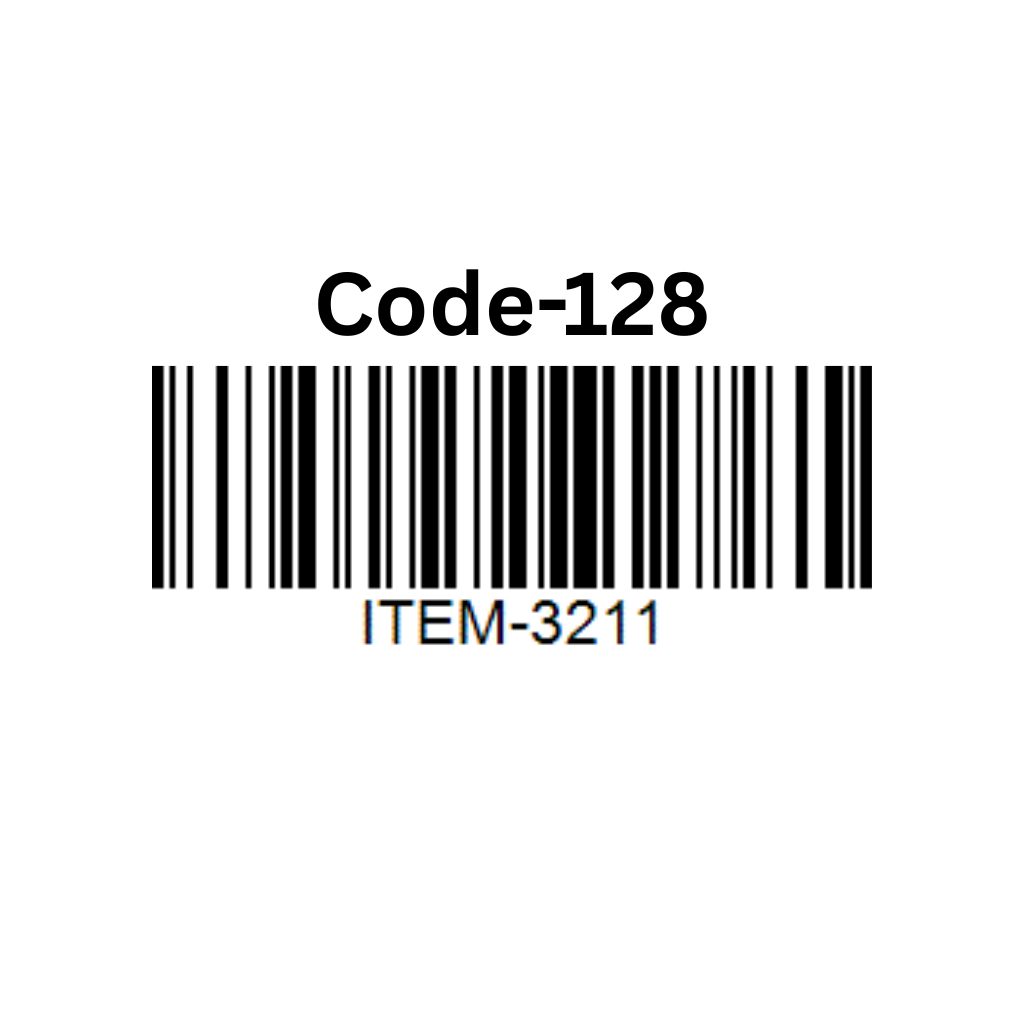

Code-128

Code 128 is a compact and versatile 1D barcode commonly used in warehousing, logistics, and inventory tracking. It can encode a wide range of characters and stores data more efficiently than Code 39, which means it fits more information into less space and produces shorter barcodes that scan reliably.

Why people use Code 128

- More compact than Code 39 (fits better on smaller labels)

- Supports numbers and letters efficiently

- Very common in warehouse and logistics environments

- Fast and reliable scanning with standard barcode scanners

Limitations

- Still a 1D barcode, so space can become an issue if many data fields are needed

- Not structured for multi-field scanning by default (treated as one value)

Best suited for

- Internal item numbers

- Carton or container IDs

- Inventory tracking labels

- Situations where a clean, compact 1D barcode is needed

QR Code

QR Codes are 2D barcodes that can store significantly more data than 1D barcodes while remaining easy to scan. They are widely recognized and work well with both industrial scanners and mobile devices like phones and tablets.

Why people use QR Codes

- Holds more information in a smaller space

- Scans easily with modern scanners and mobile devices

- Flexible, can store IDs, multiple data values, or links

- Useful for mixed environments (warehouse + mobile users)

Limitations

- Requires scanners or devices that support 2D barcodes

- Not always accepted by trading partners for shipping labels

- Needs good print quality for reliable scanning

Best suited for

- Internal inventory labels with multiple data points

- Mobile or tablet-based scanning workflows

- Labels where space is limited but flexibility is needed

DataMatrix

DataMatrix is a compact 2D barcode designed to store a large amount of data in a very small area. It’s often chosen when label space is extremely limited but reliable scanning is still required.

Why people use DataMatrix

- Very small size with high data capacity

- Excellent for tight or crowded labels

- Reliable scanning even on small items

- Well-suited for detailed, information-rich labels

Limitations

- Requires 2D-capable scanners

- Less familiar to casual users than QR Codes

- Not ideal if human readability is the primary goal

Best suited for

- Small items or components

- High-density inventory labels

- Environments with limited label space

- Operations needing compact, data-rich barcodes